CNC 5-Axis

CNC 5-Axis Custom Machining:

Overview

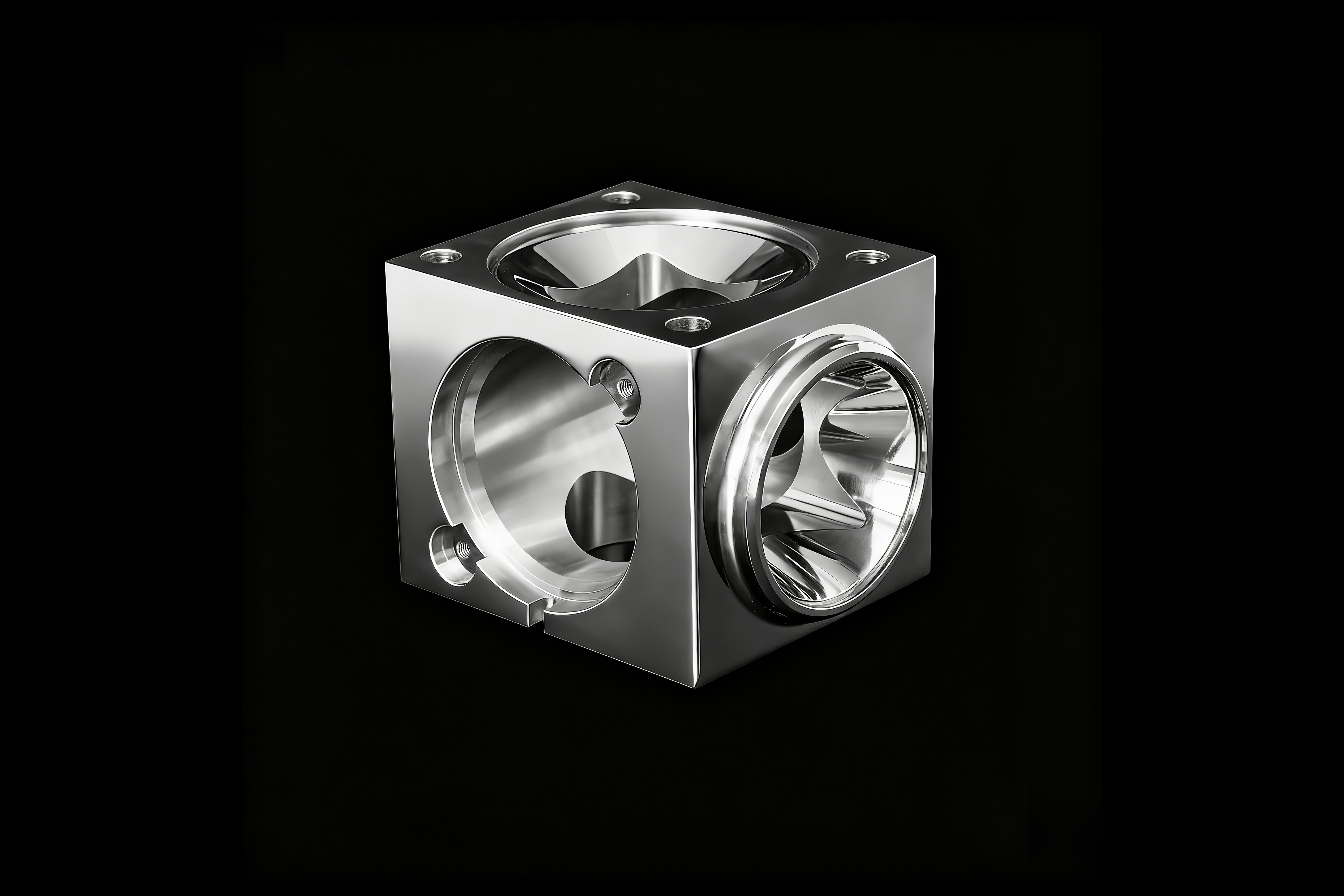

CNC 5-axis custom machining is a high-precision manufacturing technology that integrates Computer Numerical Control (CNC) with 5-axis simultaneous movement (X, Y, Z linear axes + two rotational axes, typically A/B or C) to produce complex geometries in a single setup. This method is widely used in aerospace, automotive, and medical industries for parts requiring tight tolerances (e.g., ±0.01mm) and intricate designs.

Key Features

Multi-Axis Flexibility: Enables machining of contoured surfaces, undercuts, and angled features without repositioning, reducing error accumulation.

High Efficiency: Achieves 30–50% faster cycle times compared to 3-axis machining by eliminating multiple setups.

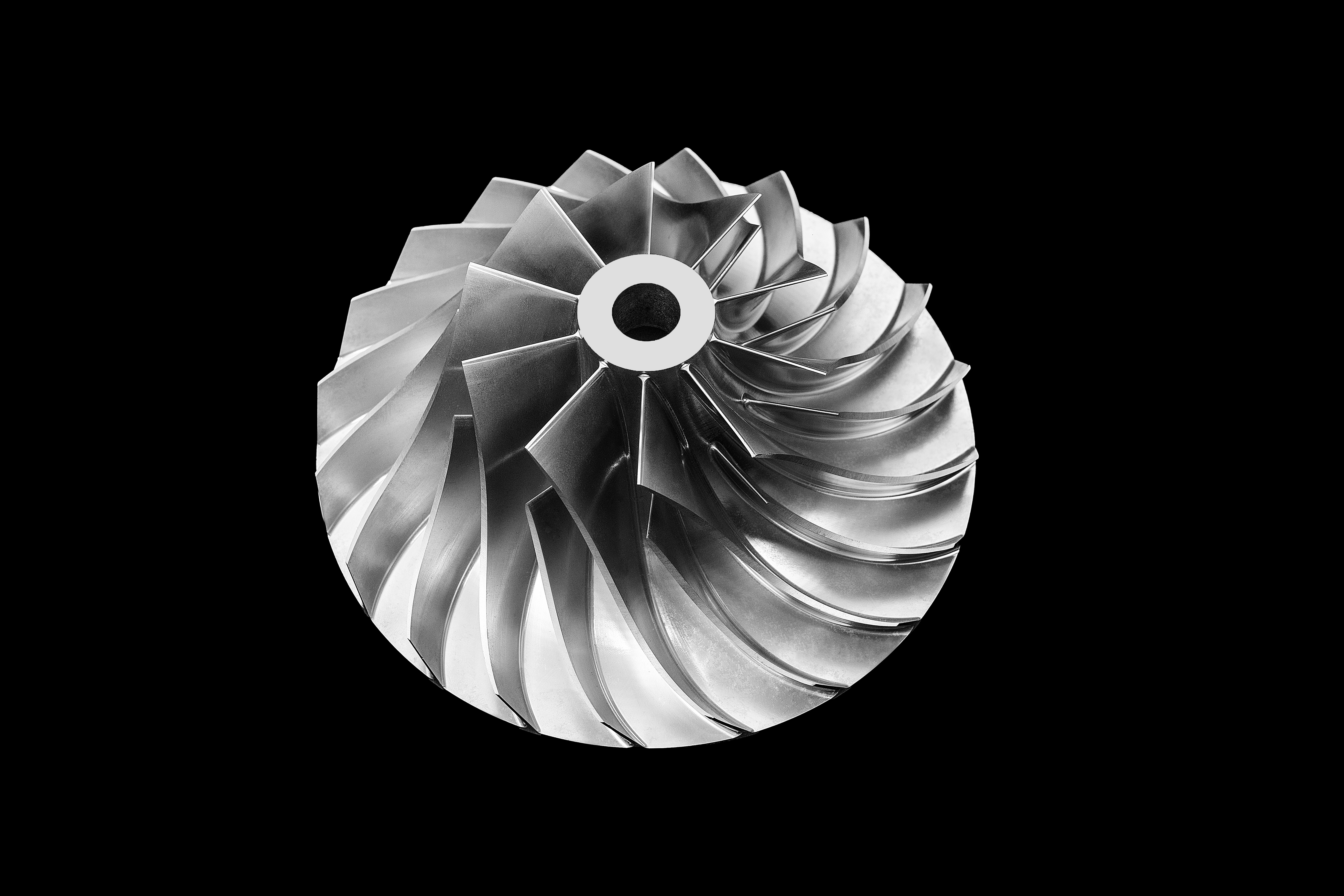

Material Versatility: Supports metals (titanium, aluminum,steel), plastics, and composites, with applications ranging from turbine blades to medical implants.

Advanced Tool Paths: Uses RTCP (Rotation Tool Center Point) to maintain tooltip accuracy during multi-axis movements

Applications:

Aerospace

Medical

Low-altitude economy

Automated robots

Electric vehicles and their accessories