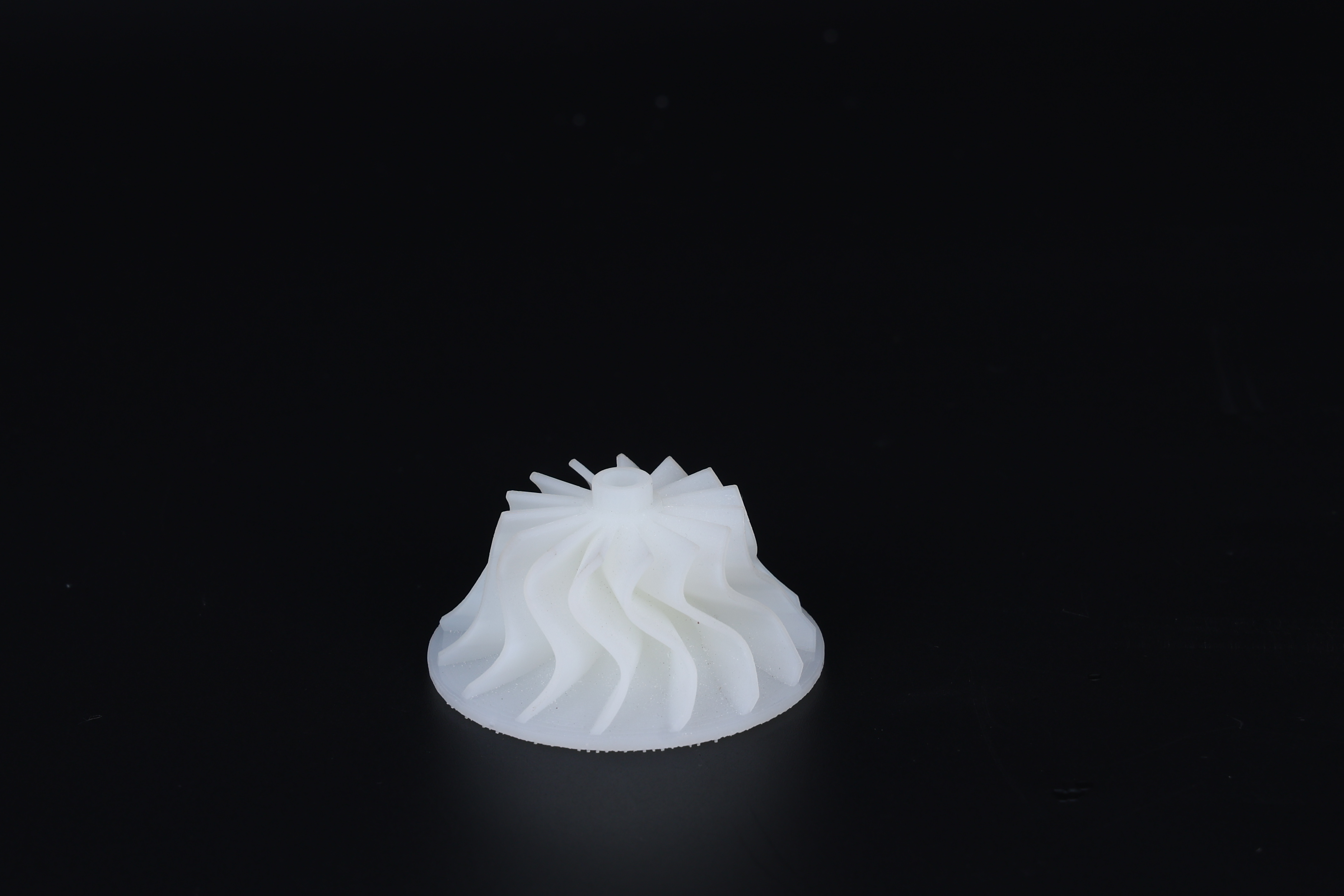

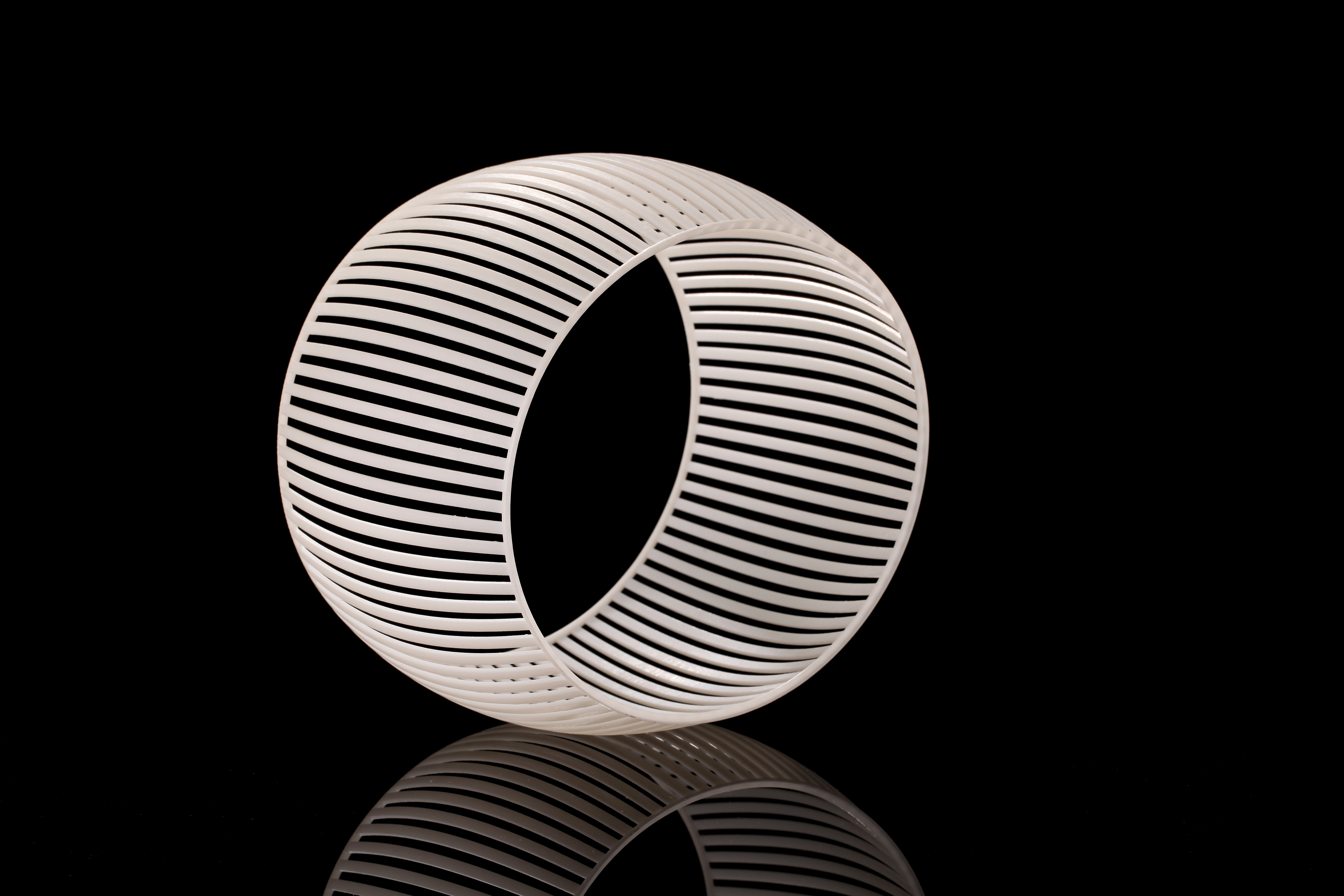

3D printed-FDM-SLA-SLS

3D printing, for plastic & metal parts, a subset of additive manufacturing, Fast & Cheaper constructs objects by depositing thermoplastic materials layer-by-layer based on digital models. The most common methods include:

Fused Deposition Modeling (FDM): Melting plastic filaments (e.g., ABS, PLA) through a heated nozzle, then extruding them layer-by-layer.

Stereolithography (SLA): Using UV lasers to cure liquid photopolymer resins into solid layers.

Selective Laser Sintering (SLS): Laser-fusing nylon or TPU powder particles into cohesive structures.

Applications to:

Industrial: Custom jigs, functional prototypes, and end-use parts.

Medical: Patient-specific anatomical models and surgical guides.

Consumer Goods: Footwear (e.g., 3D-printed midsoles), jewelry, and home decor.

Education: Hands-on STEM teaching aids for engineering concepts.

Design & presentation: Appearance verification for new product development, new product display at expos/exhibitions,handmade model, rapid prototypes,mock up model etc.