Sheet Metal Fabrication

Sheet Metal Fabrication:

Sheet metal processing involves multiple steps to transform flat metal sheets into functional parts. Below are the key processes in English:

1. Sheet Metal Cutting

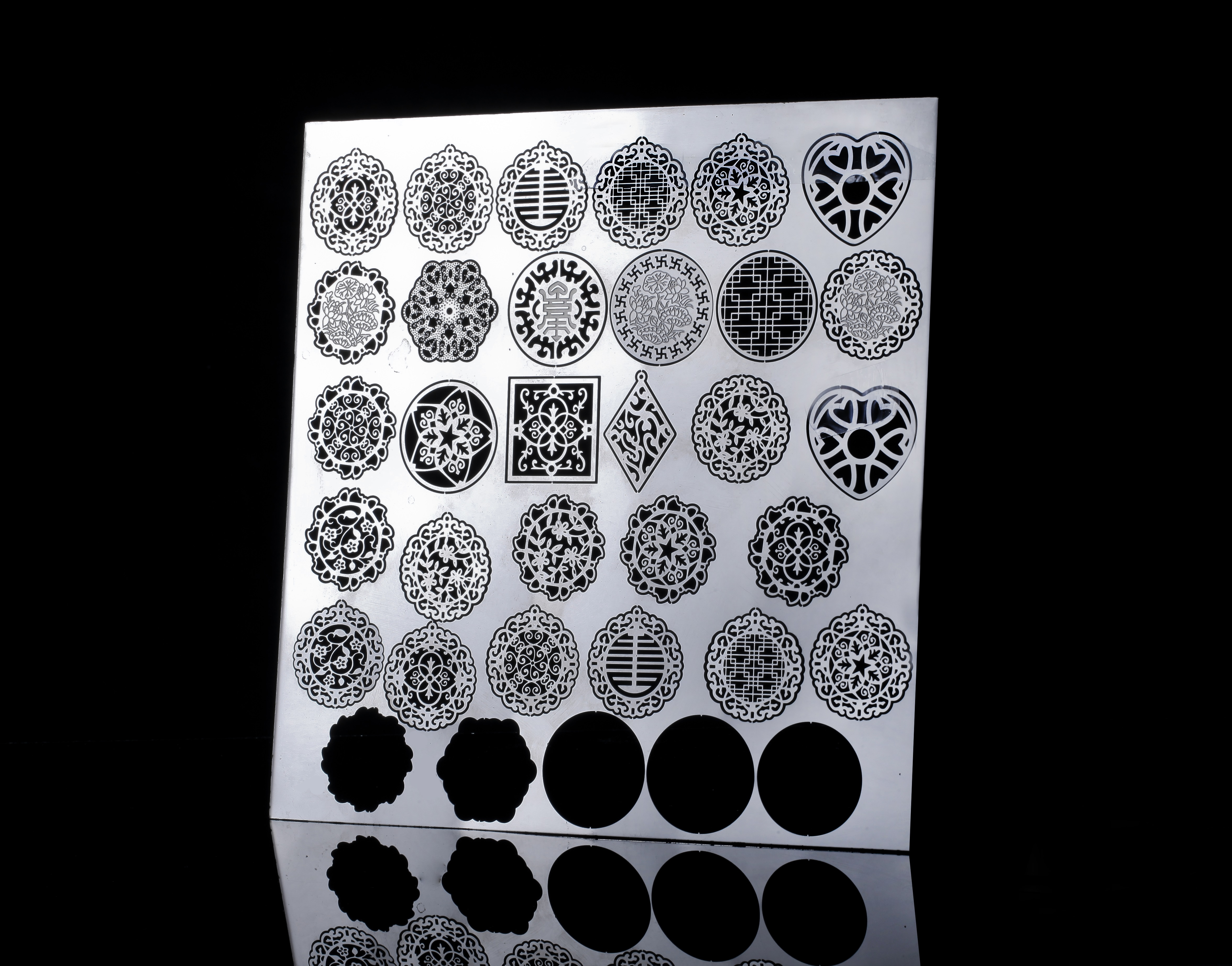

Laser Cutting: Uses a high-precision laser to cut complex shapes from metal sheets.

2. Sheet Metal Bending

Press Brake Forming: Uses a press brake to bend metal sheets at precise angles.

Roll Bending: Forms curved shapes (e.g., pipes) by passing metal through rollers.

Folding: A specialized technique for tight bends (e.g., in enclosures).

3. Sheet Metal Stamping

Blanking: Cuts out flat shapes from a metal sheet.

Deep Drawing: Forms hollow parts (e.g., cups) by stretching metal into a die.

Flanging: Creates raised edges around holes for reinforcement.

4. Sheet Metal Fastening (Riveting & Joining)

Press-Fit Riveting: Uses pressed rivets (e.g., pop rivets) to join parts.

Spot Welding: Bonds metal sheets at localized points using electric current.

Self-Piercing Riveting (SPR): Joins dissimilar metals without pre-drilling.

5. Secondary Processes

Deburring: Removes sharp edges for safety.

Powder Coating: Applies a protective finish via electrostatic spray.

Assembly: Combines multiple parts (e.g., welding, bolting).